KANEKO’S HIGH-PRECISION MACHINING

KANEKO’S HIGH-PRECISION MACHINING

Kaneko’s High-precision machining

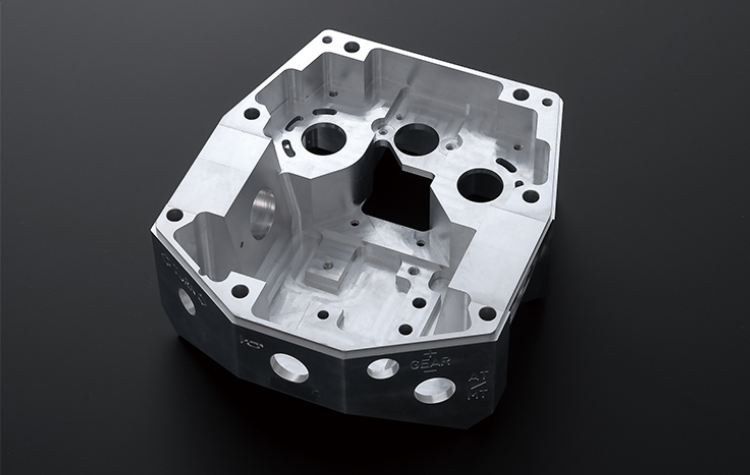

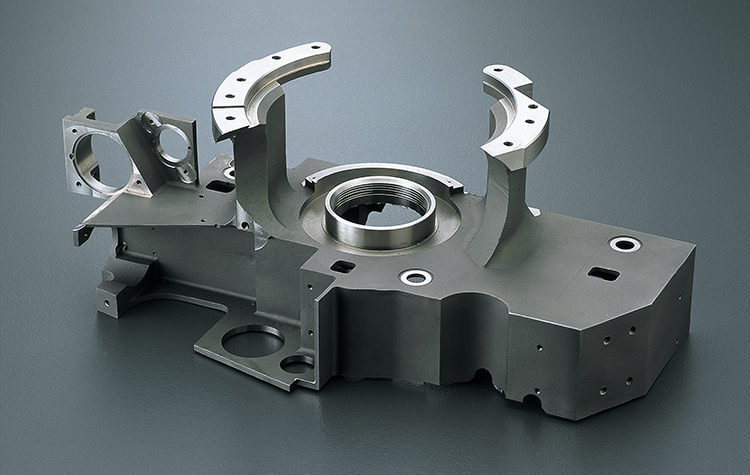

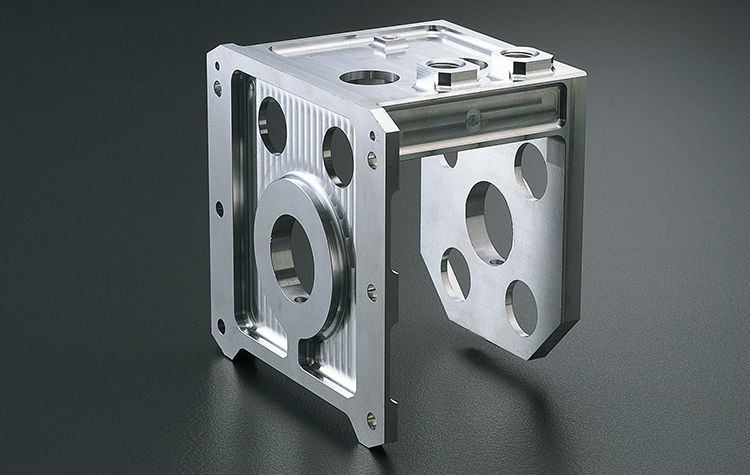

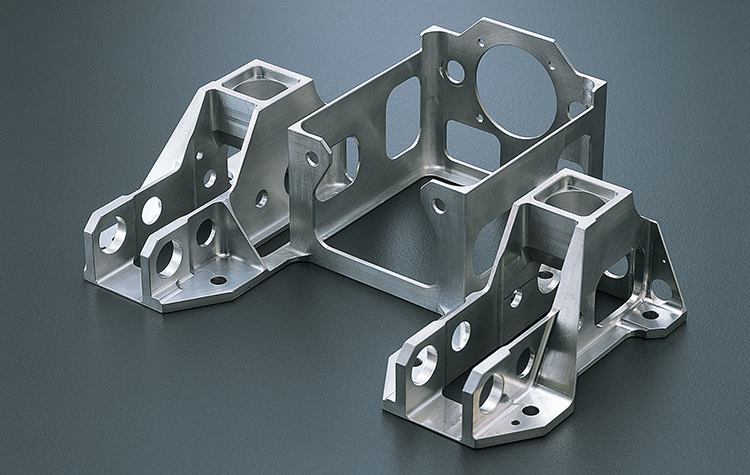

We carry out a wide range of high-precision machining work from medical equipment, aviarion, optical equipment, and various research & development.

LONG TERM RECORD OF BUSINESS TRANSACTION

The company is located in the capital “Saitama city” where is adjacent prefecture of international city Tokyo. KANEKO has over 60 years experience in machining of metal, resin, ceramic and, assembly of high-precision components. With over 40 years experience in the endoscopic field and, 30 years experience in aviation field, KANEKO will always provide the best solution and result.

RESEARCH AND DEVLOPMENT PROJECT

We calculate the labor cost which is the dominant element of the development costs in separate from the product cost. Therefore, We can undertake high difficulty of projects involving research and development is not limited to the aircraft and rocket parts, while suppressing the product cost. If you are having any problems with your current situation, please feel free to contact us.

JAPANESE QUALITY = WORLD LEVEL QUALITY

KANEKO has certified for both the medical equipment quality of ISO 13485 and aerospace quality of JIS Q 9100 (Mutual authentication to US AS9100 and the European EN9100).

We offer a high precision machining and assembly technology based on our double certification of both fields.

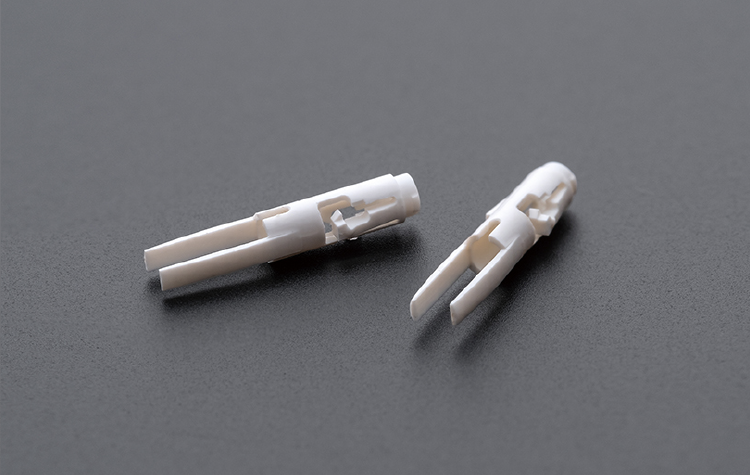

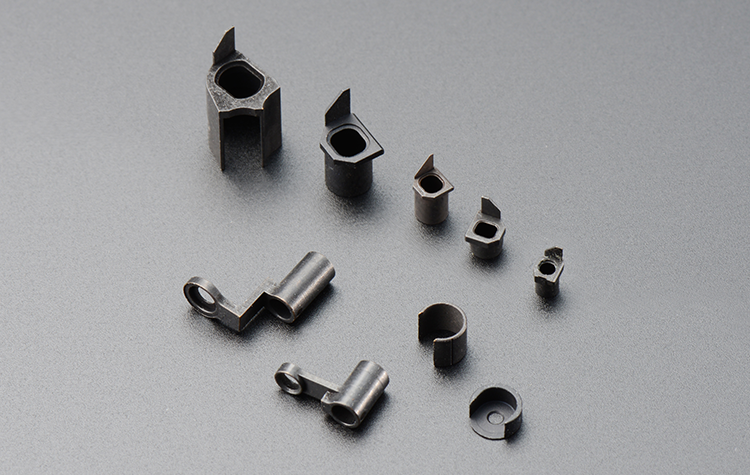

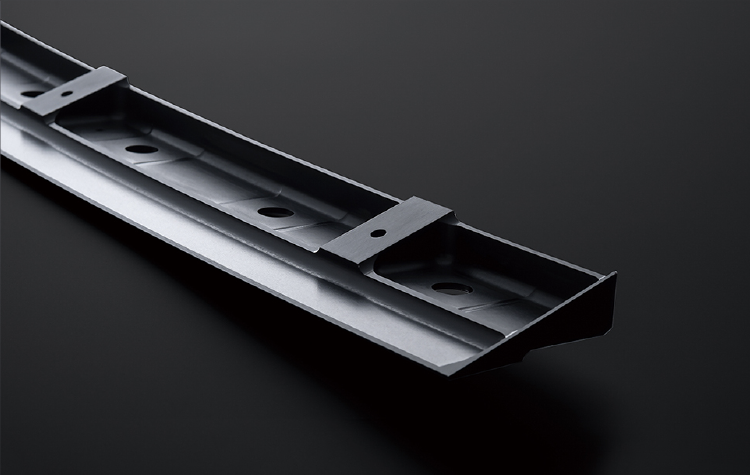

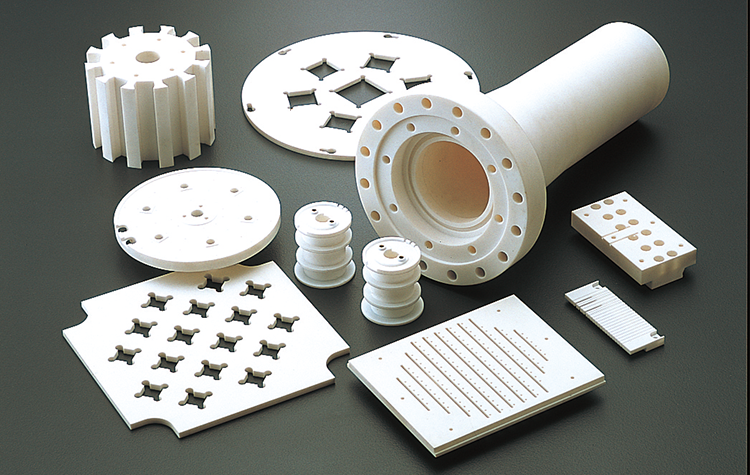

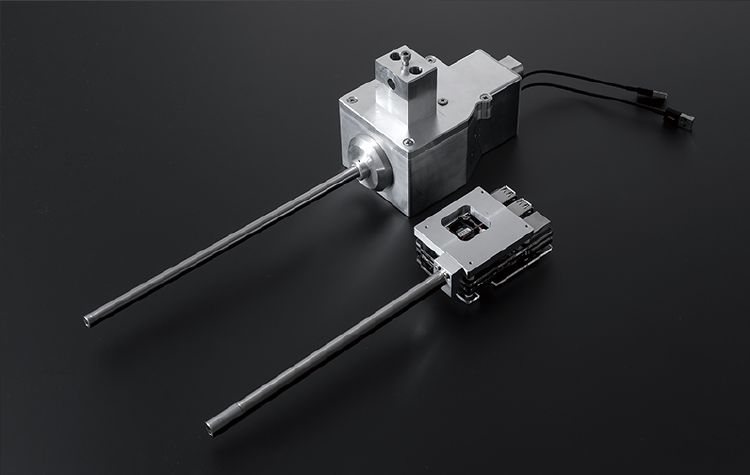

Machining example

High-precision machining for medical components

Small & Tiny

parts machining

Endoscope optical parts

Alminium/ Brass│1.4mm~5mm

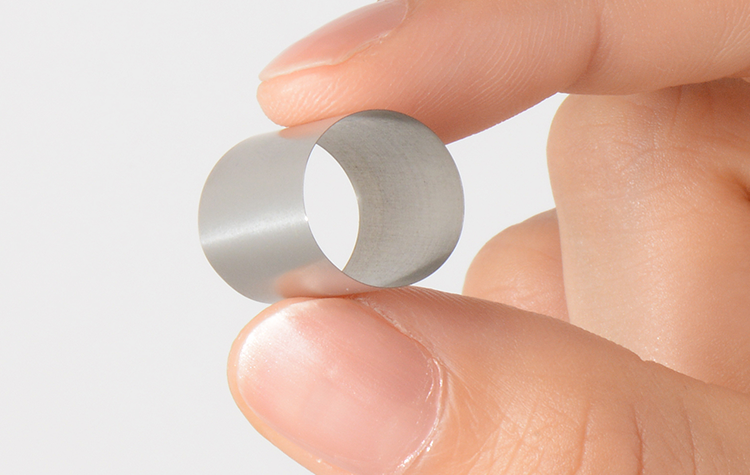

Extremely thin

machining

Sample for thin wall parts

SUS303│φ13 x t0.05mm

Small & Tiny

parts machining

Endoscope equipment

Alminium, SUS, Brass│1.2mm~5mm